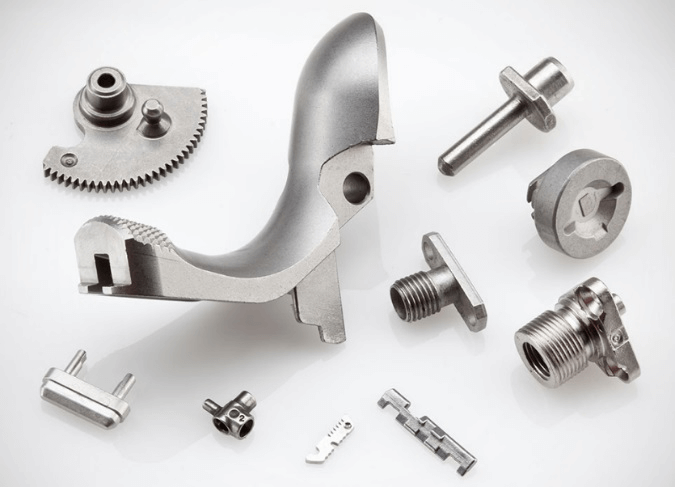

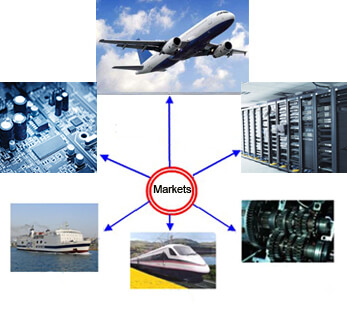

Metal injection moulding (MIM)has over the past decades established itself as a competitive manufacturing process for small precision components which would be costly to produce by alternative methods. It is capable ofproducing in both large and small volumes complex shapes from almost all types of materials including metals,ceramics, intermetallic compounds, and composites. Components made by MIM technology are finding applicationsin industry sectors such as automotive, chemical, aerospace, business equipment, computer hardware, bio-medicaland armaments.

Metal injection molding (MIM) is a development of the traditional powder metallurgy (PM) process and is rightly regarded as a branch of that technology.

Metal injection molding (MIM) is a metalworking process by which...

Carbonyl iron and nickel powders

Fortunately for Metal Injection Molding technology, very fine carbonyl iron and nickel powders were already in industrial production when the process was developed.

MIM technology combines the advantages of powder metallurgy and plastic injection molding , breaks the limits on the shape of the product of traditional metal powder press molding , and absorbs the advantages of plastic injection molding in large quantities and high efficiency of shaping parts with complex shapes.

Learn More

Metal Injection Molding (MIM) is in use in a wide variety of industries. Aerospace, semiconductor manufacture, automotive, military, and medical are just a few industries that benefit from the chemical machining technology.

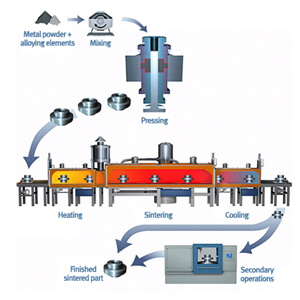

The Metal Powder Injection Molding process is typically explained as four unique processing steps (Compounding, Molding, Debinding and Sintering) to produce a final part that may or may not need final finishing operations.

Learn More

The design engineer can analyse the filling dynamics in thick and thin areas on screen, study the effects of gate position, thermal gradients in the mold and phenomena such as jetting and binder segregation.

FAQ About us Products Equipments News Contact us

MIM manufacturer MDM Metal has been focusing on the manufacturing of MIM parts, MIM Components,sintering parts and custom metal parts for years.Your satisfactory is our biggest honor.