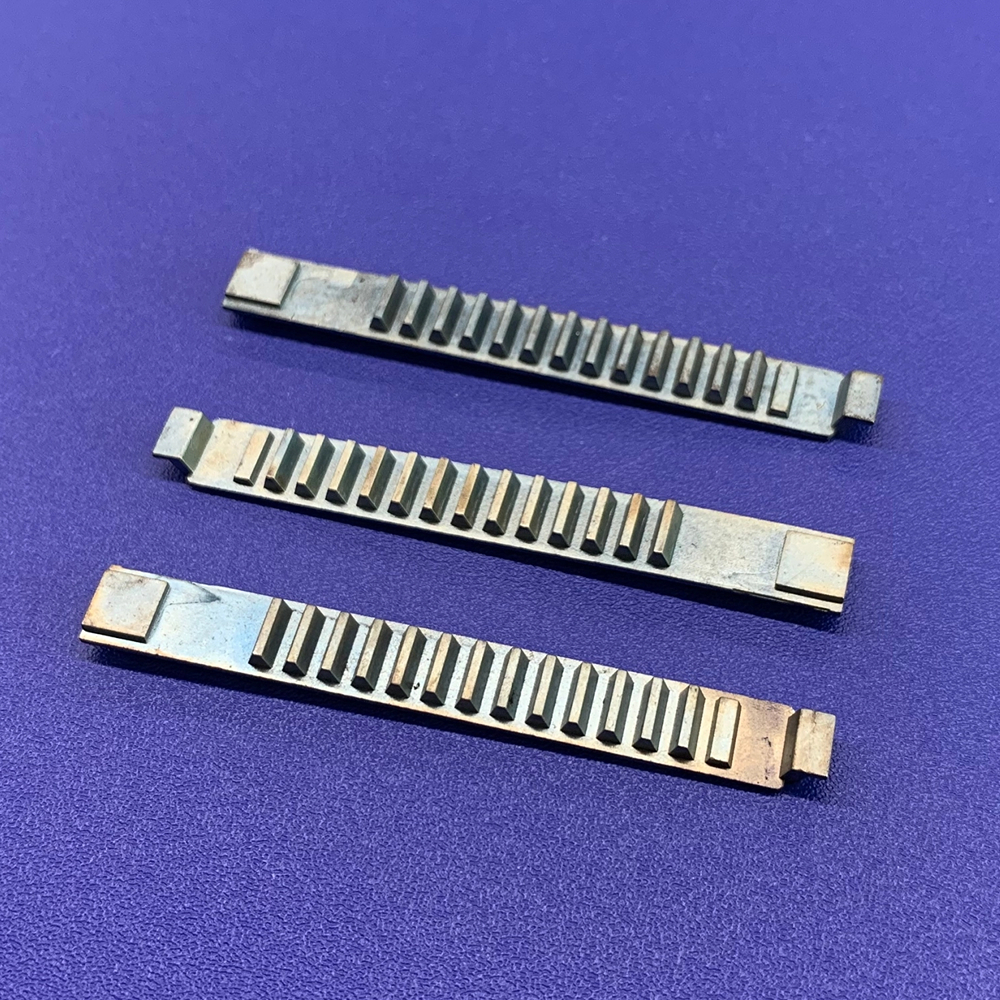

Material: MIM 4605.

Surface treatment: sand blasting and black oxide.

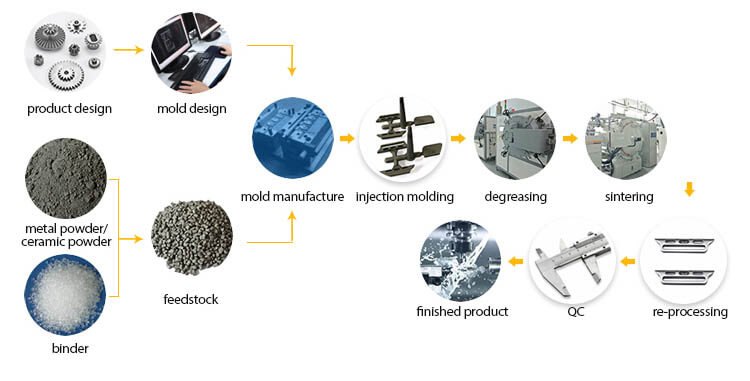

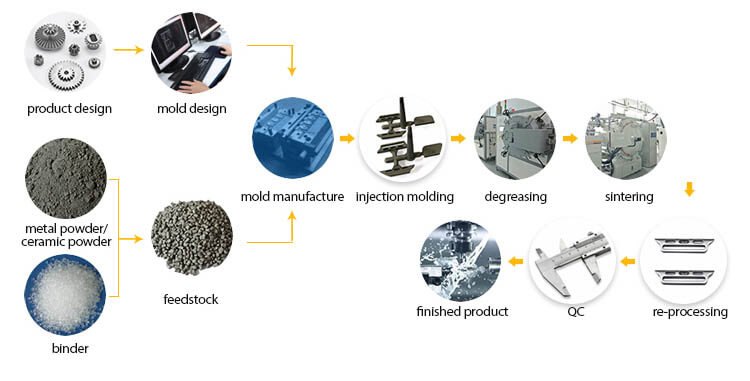

MIM is the process which merges plastic injection molding and powdere metallurgy. It offers greater design free dom and a manufacturing

capability of producing precise, complex parts in large quantities. Metal injection molding (MIM) is a manufacturing process in which a metal

powder is mixed with a polymer binder to form a material that behaves like plastic. This feed is used for injection mold mesh and precision parts.

The parts are then heat treated, the adhesive system removed, and finally sintered into high-density metal parts with mechanical properties

comparable to the forged material.

MIM technology specializes in the production of complex structural hardware accessories-Near net forming hardware parts production method.

Metal injection molding technology application fields:

1. Computer and its auxiliary facilities: such as printer parts, magnetic core, firing pin shaft pin, drive parts;

2. Tools: such as drill, cutter head, nozzle, gun drill, spiral milling cutter, punch, socket, wrench, electrical tools, hand tools, etc.;

3. Household appliances: such as watch case, watch chain, electric toothbrush, scissors, fan, golf ball head, jewelry chain link, ballpoint pen clamp,

cutting tool head and other parts;

4. Parts for medical machinery: such as orthodontic frame, scissors, tweezers;

5. Electrical parts: electronic packaging, micro motor, electronic parts, sensor parts;

6. Mechanical parts: such as cotton looser, textile machine, flanging machine, office machinery, etc.

7. Automotive and Marine parts: such as clutch inner ring, fork sleeve, distributor sleeve, valve guide, synchronous hub, airbag parts, etc.