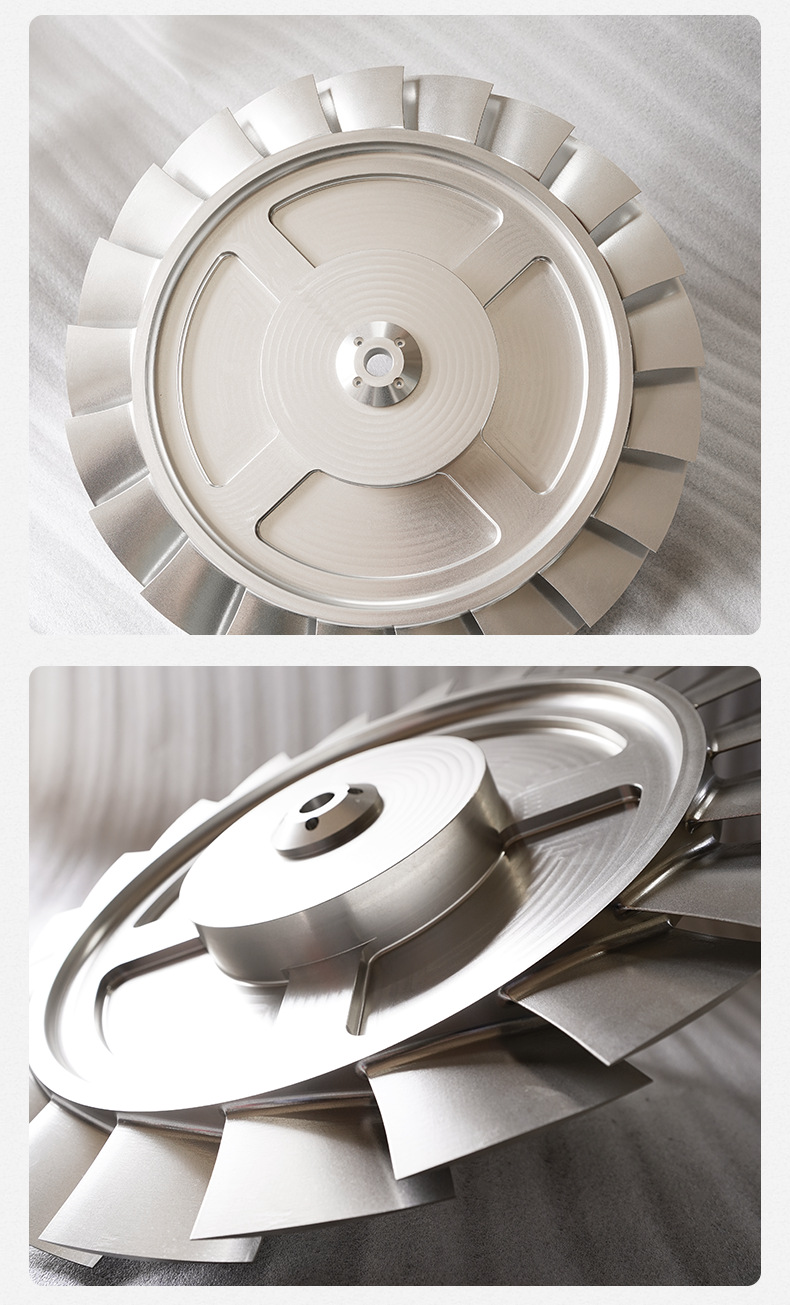

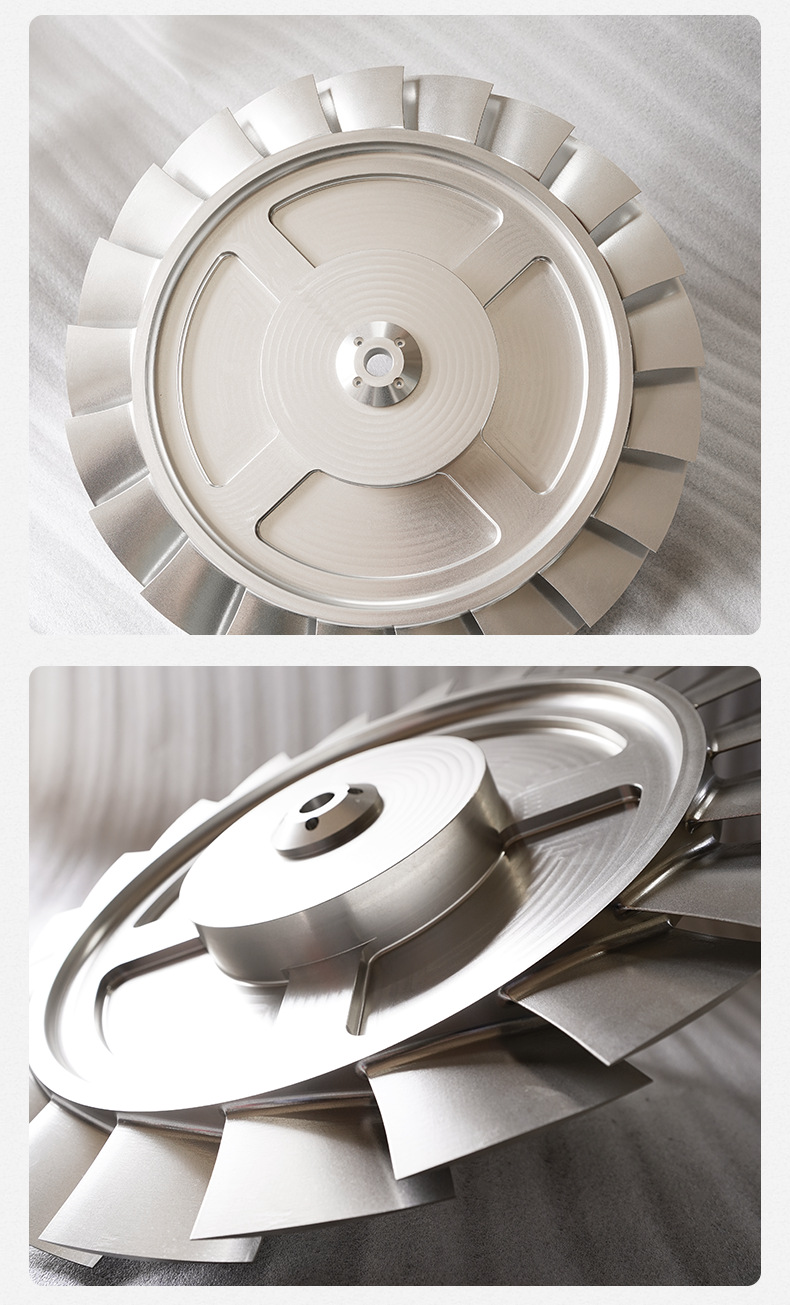

CNC Turning & Milling Aluminum Impeller | Custom Precision Parts

Materials: 6061 aluminum alloy, 7075 aluminum alloy, aviation aluminum, hard aluminum, forged aluminum, cast aluminum

Heat treatment: T6 heat treatment, Brinell hardness, Rockwell hardness, high strength, high wear resistance

Surface treatment: Anodizing, Hard Anodizing, Conductive Anodizing, Sandblasting, Mirror Polishing, Corrosion Resistance

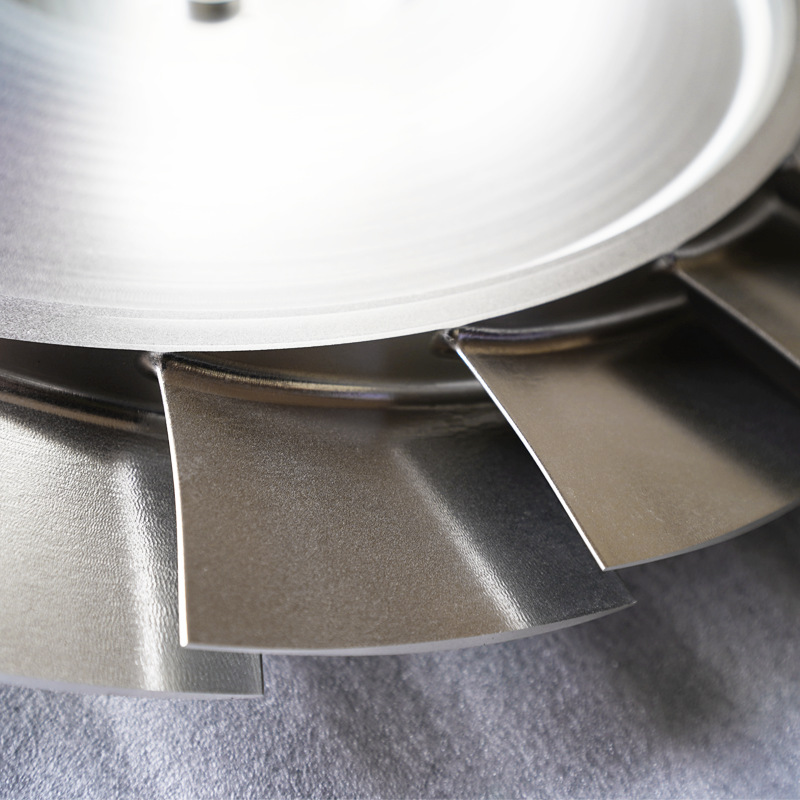

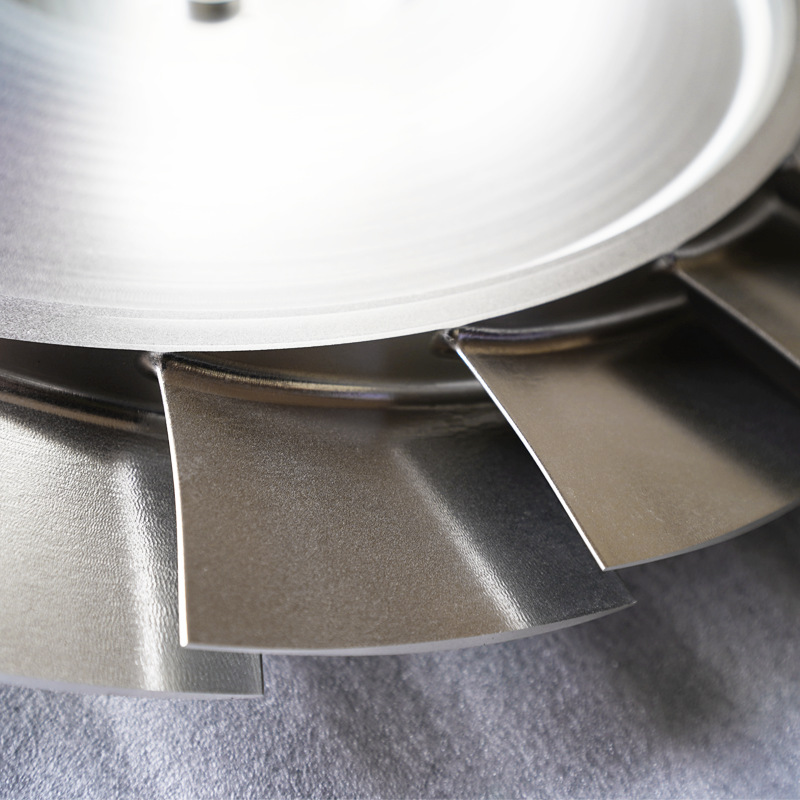

This product is a high-strength 7075-T6 aluminum alloy impeller precisely machined by CNC five-axis processing. It has undergone T6 heat treatment, with the core hardness reaching 150HB, ensuring excellent dimensional stability and wear resistance under high-speed conditions. The surface is treated with a 16μm thick hard anodizing process, with a surface hardness exceeding 500HV, and it offers excellent corrosion resistance and wear resistance. The dynamic balance level reaches G2.5, and it is mainly applied in aerospace environmental control systems, industrial turbochargers, and high-performance servo systems, which are fields with strict requirements for weight, strength, and reliability.